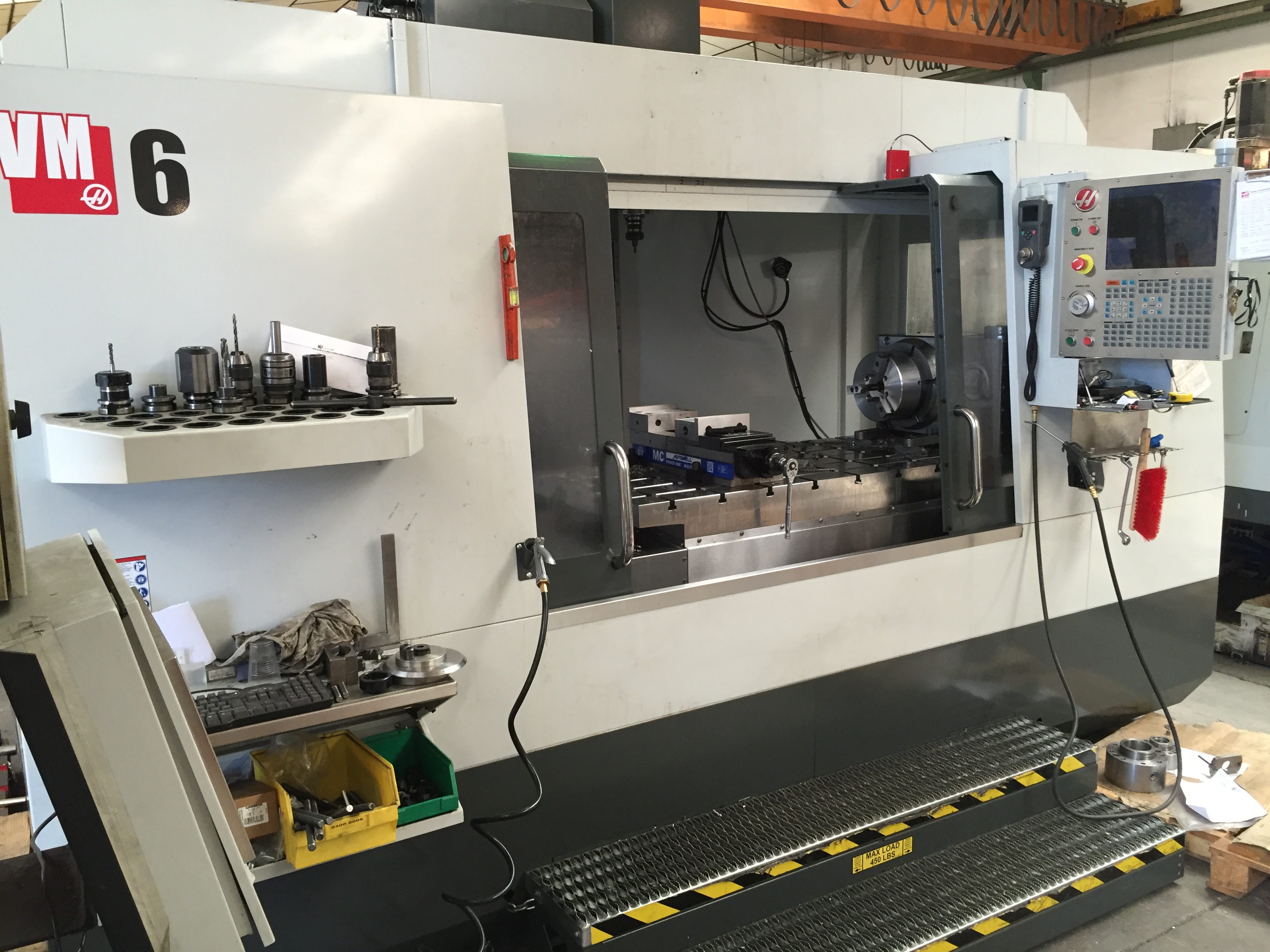

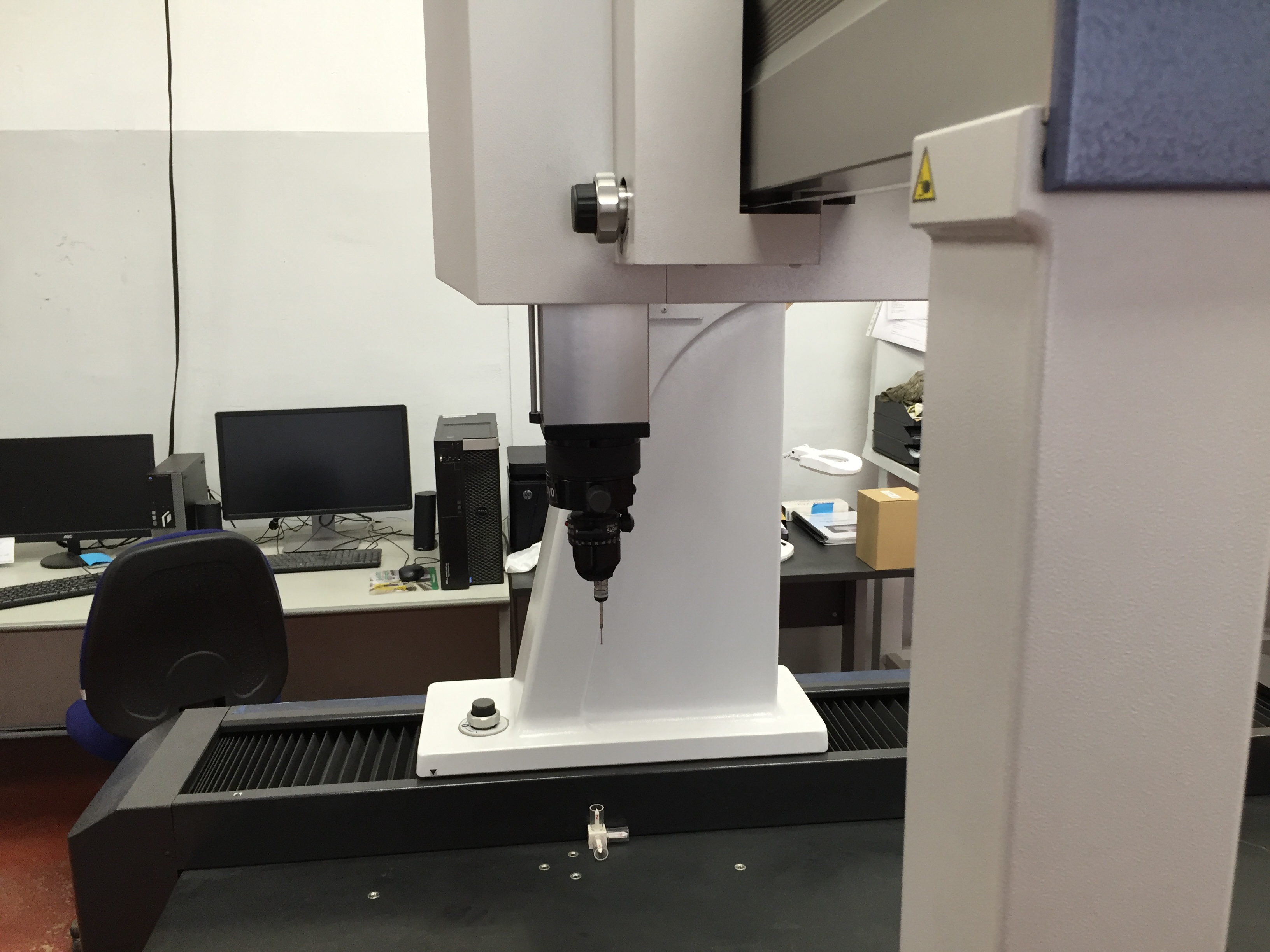

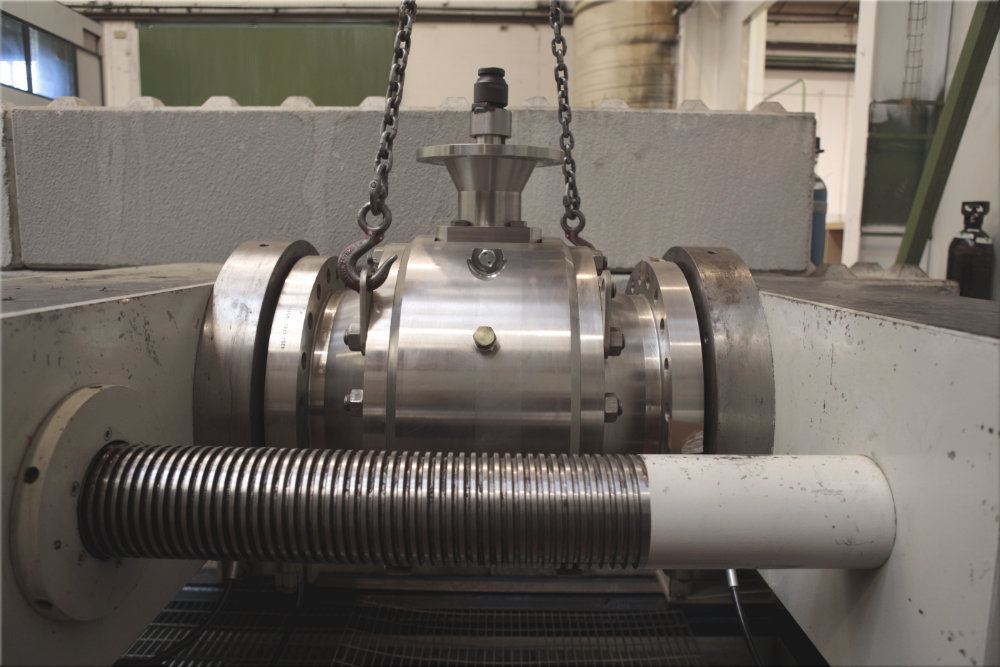

From forge to valve, all parts are machined with cutting edge technology CNC , Mills, robot and our employees are under continuous formation on the latest technologies.

Reduce time every day is very important, our manufacturing team is under continuous research on new systems and technology, to apply in our day by day manufacturing system.

A wide range of integrated factory management functions like programing, scheduling and production control enables IBOR VALVES to control the complete production process, and thus being able to guarantee lead times.

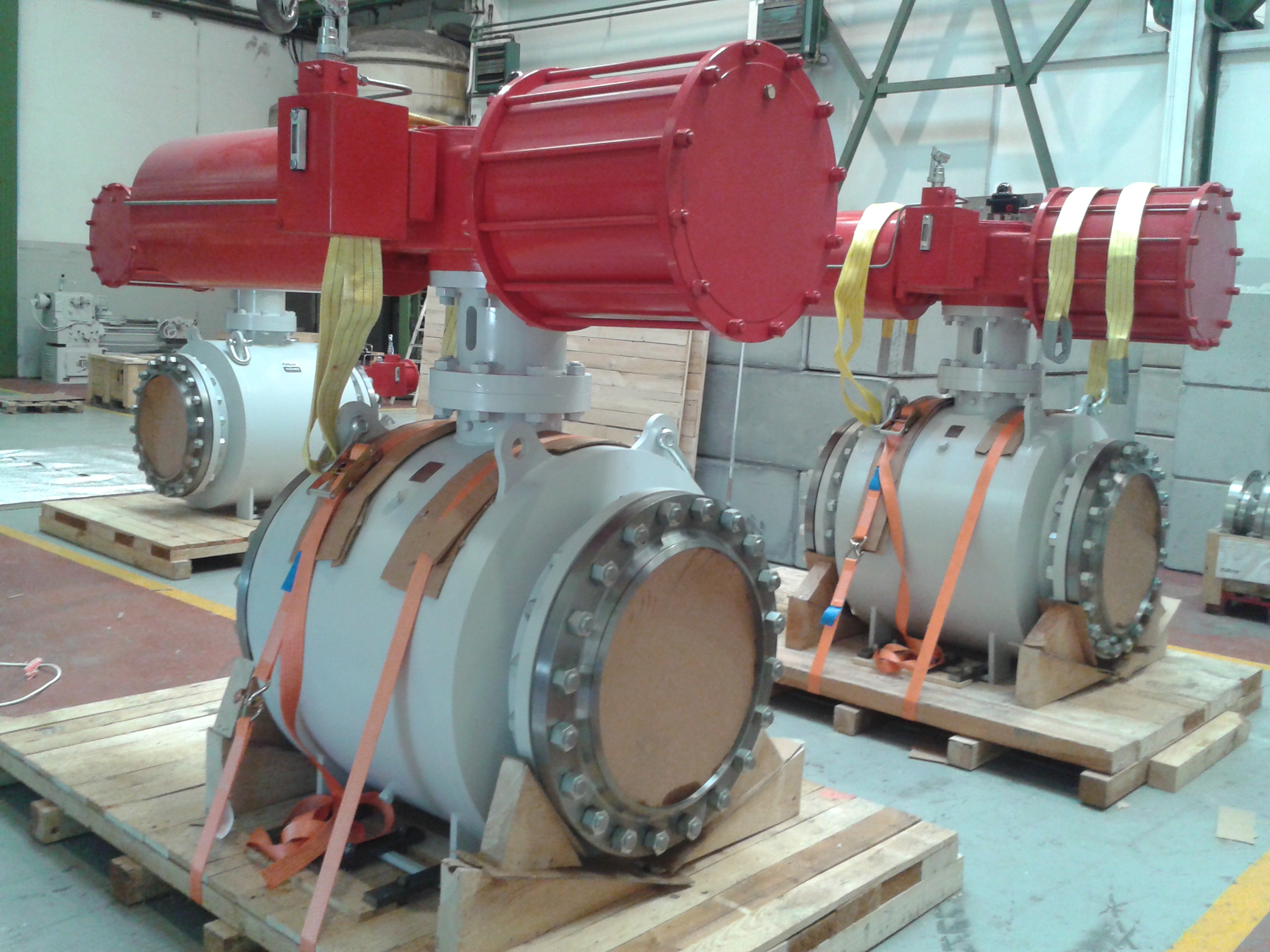

IBOR factory is ready to produce in the same way a single valve, small series and also project quantities.